Over the last few decades, China has burnished its reputation as the ‘Factory of the World’. Companies from around the world rushed to set up manufacturing plants in the East Asian nation in order to (quite sensibly) take advantage of its cheap labour, plentiful resources, and the various incentives on offer. Easy access to ports and shipping lines meant that companies could afford to hold minimal inventories and follow a JIT (Just-In-Time) inventory control philosophy, leading to higher profits and lower prices for customers. Everything went off without a hitch, until COVID-19 brought global trade to a halt.

The global trade apparatus is a giant, complex machine with many moving parts. And it’s not easy to get a machine going again when it suffers an abrupt breakdown. Of course, Chinese factories resumed production before long, but it wasn’t as instantaneous as one would have liked. Like a rusty old car that creaks, groans, and then slowly sputters to life on a cold day, it took some time for normalcy to return and in the meantime, consumers worldwide had to put up with shipping delays or go through the hassle of asking for refunds from retailers.

Naturally, this experience forced many companies, especially in the US and Europe, to rethink how their supply chains work. Instead of concentrating manufacturing bases in one country, many are now looking to diversify their supply chains for economic reasons and also as a precaution.

Countries in South and South East Asia stand to benefit the most from this change in how some of the world’s biggest companies think about their supply chains. Vietnam, Thailand, Malaysia, Bangladesh and India have often been touted as the next big destinations for manufacturing, and for good reason too. Their economic standing and resource endowments are quite similar to what things were like in China a few decades ago, when Western companies rushed to set up factories in locations such as Shenzen, Guangdong and Zhengzhou. With analysts estimating that the global trade volume from the South and South East Asian region could reach USD 150 billion over the next 4 to 5 years, Sri Lanka should capitalize on this once-in-a-lifetime chance to position itself as a key trade partner for the region.

Okay..but how?

We’ve all heard the example of how an iPhone assembled in China, is actually made up of parts that are shipped in from 43 countries across 6 continents. This is what is known as a global value chain. Companies like Apple get to source the best and the cheapest components from all around the world, while individual suppliers in countries get the chance to undertake very profitable orders with quite significant volumes. Take for instance Asahi Glass, which manufactures the screen glass on an iPhone. Though the component itself is quite small, insignificant, and sold to Apple for a few dollars at best, the total value of the millions of screen glasses shipped every year is a lot. That is why companies like Asahi and Sharp of Japan are quite content to be suppliers of small components, rather than trying to build their own smartphones.

And that’s what Sri Lanka must try to emulate.

After all, the country is located right beside some of the world’s most important shipping routes, and is located close to countries like Bangladesh, India and Vietnam. This alone gives Sri Lanka a good chance of plugging into the global value chains that will be created by companies setting up manufacturing facilities in the region.

However, before it can get there, Sri Lanka must align its economic capabilities to suit the manufacturing needs of its future trading partners. Doing this would most likely require investments and reforms in both hard and soft infrastructure, which must be identified and implemented quickly.

This is where ‘TradeShifts’— an exercise that aims to help Sri Lanka identify lucrative economic opportunities that can come about as a result of this anticipated shift in regional manufacturing , becomes useful.

How TradeShifts works

The TradeShifts project is carried out by AmCham Sri Lanka in partnership with USAID, and consists of three phases, of which the first two have already been completed. Presantha Jayamaha, President of AmCham Sri Lanka, told Roar Media that “Through TradeShifts, we aim to analyse and identify the potential shifts in industries and sectors at a macro level, relate them to available opportunities at a micro, internal level in order to ascertain the ‘low-hanging fruit’ for Sri Lankan companies, agree on the necessary policy developments to attract these opportunities, engage with the Government of Sri Lanka to implement these policy reforms to develop the business environment, and proactively engage with potential US businesses that are in the process of supply chain diversification”.

Under the first phase, funding from USAID has been utilized to prepare a report that identifies the likely future shifts in supply chain strategies across the short- and medium-term, the drivers of such shifts, and their implications for Sri Lanka. This report has been prepared by Stewart Pierce-Gardiner and his team from Deloitte LLC, the global audit and consulting giant.

Based on the findings of the report and other supporting literature, AmCham Sri Lanka, the Export Development Board and the Board of Investments of Sri Lanka have collaborated to identify the top five sectors which stand to gain the most from the upcoming shift in global supply chain structures.

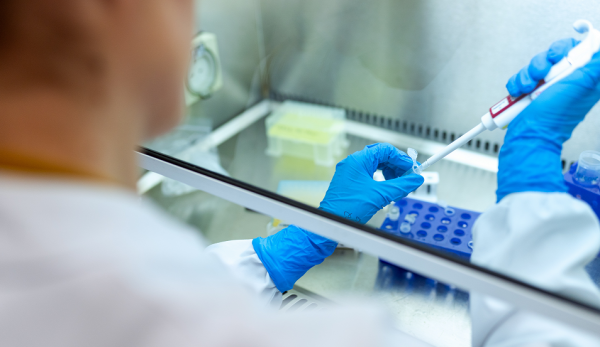

During the second phase of the project, forty representatives from 18 industries in the aforementioned five sectors participated in a three-week long series of consultations to discuss, brain-storm and identify the opportunities and challenges they may face when trying to attract business from manufacturers who set up base in South and South East Asia. Industry representatives who participated in the sessions include those from the Seafood Exporters Association, the Sri Lanka Electronic Manufacturers & Exporters Association, the Sri Lanka Automobile Component Manufacturers Association, the Sri Lanka Pharmaceutical Manufacturers Association, the Joint Apparel Association Forum, and more.

After the successful completion of the second phase of the project, the TradeShifts project team will sift through everything they’ve learned. They will then put together a data-driven, practical, and business-relevant white paper which will be presented to the Government, so that the policy makers of the country can do what is necessary to help Sri Lanka be on the right side of the shifting global trade and manufacturing landscape. That will be the stepping stone for the third and final phase of TradeShifts, by the end of which Sri Lanka will gain access to an an in-depth go-to-market strategy that can serve as a blueprint to grow the country’s economy by capitalising on the changing patterns of global trade.